Refinery and Solvent Product

Desolventiser

Toaster (D.T.)

Preconditioner Cooker

Reaction Vessels

Material Handling

Equipments

Spares

Rotary Valves

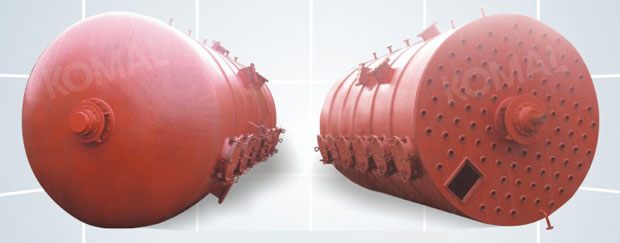

Preconditioner Cooker

This conditioning procedure is vital to the pre-treatment of most oilseeds and consists of a heating of the seed with an adjustment in the moisture content. The reasons for cooking are complex and not applicable for all seeds but the following points should be noted:

- Adjustment of the natural moisture content of the seed for optimum extraction

- To decrease the viscosity of the oil to allow it to flow more readily in the extraction process

- To complete the rupturing of the oil cells initiated in the breaking and rolling stages which is partially achieved by removing moisture

- To coagulate the protein in the seed which renders the oil separate from the seed without losing the proteinacous solids

- To sterilize the seed and stop enzyme action responsible for bacterial growth and possible mould formation

- To detoxify undesirable seed components which would render the cake unusable (e.g. gossypol in cottonseed) for animal feed purposes

- To fix certain phosphatides in the cake or meal and lower subsequent oil refining.

The operation is usually carried out in a stacker cooker, of vertical design where the seed moves down through up to eight trays each with its own stirrer system mounted on a common vertical shaft, the diameter of the stack and number of trays depends on the capacity required and seed being processed.

A small quantity of direct steam can be injected at the top trays to heat the seed and improve the rupturing of the oil bearing cells, after that the steam coming from the vaporization of the seed moisture is sufficient. The stirrers agitate the material to ensure uniform cooking and provide a means transferring meal through successive compartments. Seed levels and overall residence times are easily adjustable.